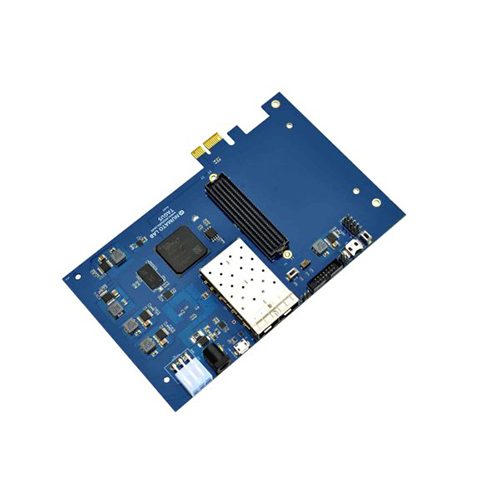

Tagus A7 PCI Express Development Board

Tagus A7 PCI Express Development Board Specification

- Soldermask

- Green

- Silkscreen

- White

- Flame Resistance Level

- UL94 V-0

- Min. Line Spacing

- 0.13mm

- Min. Line Width

- 0.13mm

- Test

- 100% E-test

- Board Type

- PCI Express Development

- Impedance

- Controlled, 50

- Hole Size

- 0.2mm (min)

- Voltage Endurance

- 50V DC

- Insulation Resistance

- >500 M

- Product Type

- FPGA Development board

- Base Material

- FR4

- Surface Finish

- ENIG (Electroless Nickel Immersion Gold)

- Copper Thickness

- 1oz

- Board Thickness

- 1.6mm

- Color

- Green

- Panel Size

- 140mm x 95mm

- Sensor Switch

- No

- Electrical Components

- Includes Artix-7 FPGA, PCI Express Edge Connector, DDR3 Memory

- Number Of Layers

- 4

- FPGA Chip

- Xilinx Artix-7 (XC7A35T)

- Operating Temperature Range

- 0C to +70C

- Connectivity

- PCI Express x1 Gen2 Interface

- LED Indicators

- 8 user LEDs

- Memory

- 512MB DDR3 SDRAM

- Programming Interface

- JTAG

- On-board Oscillator

- 50MHz

- Expansion Interface

- Pmod, FMC Standard Compatible

- RoHS Compliance

- Yes, Lead Free

- PCB Finish

- Glossy

- Mounting Holes

- M3, 4 corners

- Button/Switches

- 4 user push-button switches, 4 DIP switches

- Power Supply

- PCIe Bus-powered or External 5V Input

Tagus A7 PCI Express Development Board Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 1-4 Days

About Tagus A7 PCI Express Development Board

Features

- FPGA: AMD Artix-7 XC7A200T in -2 FBG484I package

- 1 lane PCIe Gen2.0(5.0GT/s)

- DDR3: 2Gb DDR3 (MT41J128M16HA-125:K or equivalent)

- 128 Mb QSPI flash memory (N25Q128A13ESE40E) for Configuration and optional data storage

- USB to UART serial converter

- 1 x 100MHz CMOS oscillator

- Maximum 68 IOs for user-defined purposes on ANSI/VITA 57.1 Standard-compliant FMC LPC connector

- 1x GTP lanes up to 6.6Gbps on ANSI/VITA 57.1 Standard-compliant FMC LPC connector

- 1 RGB LED for custom use

- 1x Trusted Platform Module (ATXXXXXX )

- Dual SFP Cages

- MicroSD adapter for bulk data storage

- Onboard voltage regulators for single-power rail operation

- Can be powered from a PCIe slot or an external power supply

- JTAG header for programming and debugging

- All differential pairs are length matched on the board

Applications

- Parallel Processing and Accelerators

- Product Prototype Development

- Development and Testing of custom-embedded processors

- Signal Processing

- Communication Device Development

- Data Acquisition

- Educational tool for Schools and Universities

Versatile FPGA Development Platform

Experience flexible and scalable development with the Tagus A7 PCI Express Board, centered on the powerful Xilinx Artix-7 (XC7A35T) FPGA. Its combination of high-speed memory, PCIe Gen2 connectivity, and extensive user interfaces makes it suitable for a broad range of applications, from learning environments to industrial prototyping.

Seamless Expansion and Connectivity

Equipped with Pmod and FMC standard interfaces, the board allows straightforward expansion for custom peripherals or testing modules. The onboard DDR3 memory and PCI Express edge connector ensure high-speed data communication for demanding projects, all powered efficiently through PCIe or an external 5V input.

FAQ's of Tagus A7 PCI Express Development Board:

Q: How can I program the Tagus A7 PCI Express Development Board?

A: The board is easily programmed via the onboard JTAG interface, compatible with standard Xilinx programming tools such as Vivado design suite. Simply connect your programming cable to the JTAG header and follow your preferred development workflow.Q: What are the power supply options for this development board?

A: The board can be powered directly from the PCI Express bus or using an external 5V input. This dual power option offers flexibility for development and deployment in diverse environments.Q: When is it beneficial to use the PCI Express x1 Gen2 interface on this board?

A: Employ the PCIe x1 Gen2 interface whenever you need high-speed data transfer between the FPGA board and a host system, such as for real-time data processing or interfacing with PC-based applications.Q: Where can the Tagus A7 board be mounted?

A: With M3 mounting holes at all four corners, the board can be securely installed in custom enclosures, development racks, or test benches, facilitating safe and stable project setups.Q: What process is involved in interfacing additional modules via the expansion interface?

A: You can utilize the Pmod and FMC standard compatible headers to connect expansion modules, such as sensors or custom boards. Simply plug compatible modules into the respective headers, configure your FPGA design, and begin utilizing the extended features.Q: How can I monitor or debug my design with the onboard features?

A: The board provides 8 user-controlled LEDs, 4 push-buttons, and 4 DIP switches, which you can assign within your FPGA design as status indicators or user-input devices for rapid debugging and prototyping.Q: What are the benefits of the board's RoHS compliance and quality construction?

A: Being RoHS compliant and built with lead-free processes on a 4-layer FR4 PCB with ENIG surface finish, the board ensures durability, environmental safety, and reliable signal integrity, ideal for critical prototype and production applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FPGA Boards Category

Nereid K7 PCI Express FPGA Development Board

Price 110000 INR / Unit

Minimum Order Quantity : 1 Unit

Board Type : Rigid

Product Type : FPGA Development board

Sensor Switch : No

Copper Thickness : 1 oz

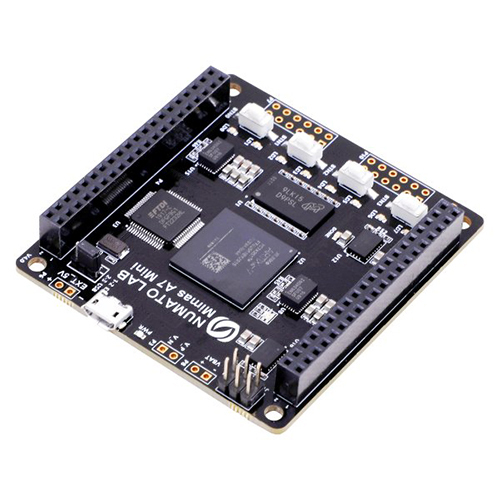

Mimas A7 Mini FPGA Development Board

Price 16500 INR / Unit

Minimum Order Quantity : 1 Unit

Board Type : Rigid

Product Type : FPGA Development board

Sensor Switch : Tactile Push Button

Copper Thickness : 1 oz

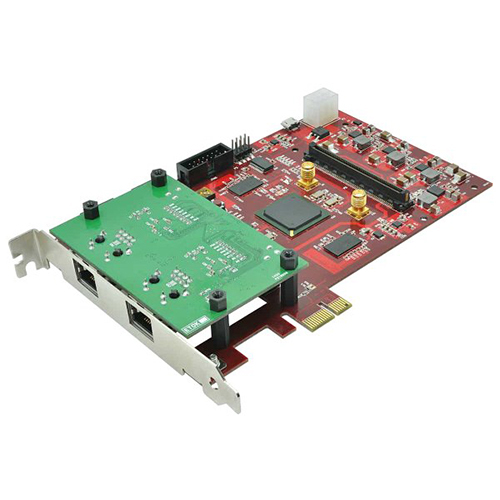

Galatea PCI Express S6 FPGA Development Board

Price 30030 INR / Unit

Minimum Order Quantity : 1 Unit

Board Type : Other, PCB

Product Type : FPGA Development board

Sensor Switch : No

Copper Thickness : 1 oz

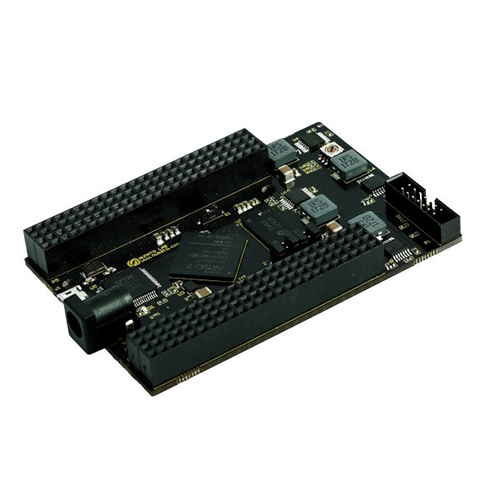

Neso A7 FPGA Development Board

Price 35200 INR / Unit

Minimum Order Quantity : 1 Unit

Board Type : Other, SMD, Through Hole

Product Type : FPGA Development board

Sensor Switch : Push Button, DIP Switches

Copper Thickness : 1 oz

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free